How can we help?

Mission Statement

Expeditiously inspire the implementation of exemplary solutions for

Reliability Maintenance Materials Management and beyond.

Project Management

Reliability Maintenance single and multi-site project management.

Maintenance, Repair, and Operations materials and standard services [MRO] Project Management.

Projects continue to be completed as expected, both on-time and within budget.

Current Practices Assessments

Well established method to quickly evaluate the ways in which work is currently performed through data analysis, interviews, and observations.

Present a Business Case when valuable opportunities from findings have been determined.

Business Processes Development

MRO foundation processes and user guides allows for accelerated customization and implementation.

The 20 foundation packages each include a flowchart, procedure, role assignments, and activity tools.

Parts Identification & Data Cleansing

Customizable software to record or cleanse the detailed identification of tangible materials and standard services that are utilized within the maintenance function.

Preparation of data upload templates.

Parts Criticality Assignment

Customizable tool utilized to determine and assign each material’s criticality level for the organization as a whole.

Knowing each material’s importance allows for all employees and suppliers to prioritize efforts and adjust stocking levels to reduce risks of shortages.

Stock/Non-Stock Determination

This customizable tool recommends when items with forecasted usage should be stocked onsite.

Special circumstances also exist that require stocking when no usage is anticipated to mitigate risk to humans, extended equipment downtime, etc.

Inventory Optimization

Carrying the proper levels of inventory manages holding costs while continuing to support maintenance and operations at your required service level.

Reorder points and Reorder quantities are established to optimize on-hand levels.

Inventory Accuracy

System quantities must match actual inventory on-hand quantities to provide confidence of supply availability to inventory requesters.

Cycle Counting identifies inaccuracies that are investigated to determine root causes and possible corrective actions.

Bills of Materials Development

Maintenance bills of materials provide easy and proper material selection for asset repairs, job cost estimating, etc.

Through manuals, equipment walkdowns, and communications with your team, we establish these for you.

Manufacturer Obsolescence Management

Lack of supply, due to manufacturer obsolescence, can lead to extended asset downtimes. Proactive and preplanned reactive methods can be established to avoid or mitigate risks.

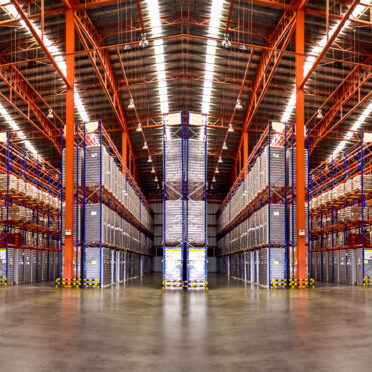

Warehouse Design and Layout

Whether you are establishing a new warehouse or reorganizing the current warehouse, we are able to provide a design and layout based on best practices and your unique needs.

Key Performance Indicators

Based on the goals of your organization, measurements are put in place to continuously strive to meet the targets of these goals.

We help with determining the proper calculations, presentation method, root cause analysis whenever target achievement is deficient, and solutions.